MIL-PRF-32504

fabric and accessories. The structure shall be fully re-locatable, allowing for disassembly and reuse of all

components (except anchors) without any additional fabrication, welding of structural components or

replacement of fabric. Shelter shall not require the use of Material Handling Equipment (MHE) for

installation or disassembly. The MLAMS Type A, Type V and Type S shall provide an unobstructed and

weatherproof covered area with no internal posts or supports. The Type A interior dimensions shall allow

adequate vertical clearance for removing CH-47 rotor blades, hubs and shafts and mast mounted sights,

allowing enough lateral clearance to rotate rotor systems 360 degrees under blackout conditions. The

basic MLAMS components are considered to be as a minimum; the structural members; weather barrier

fabric; insulation kit (if applicable); shelter erection kit; lighting and electrical system; ventilators; shelter

anchoring system; operators manual; and shipping containers. The shelter shall allow for all fabric shell

panels and optional inner liner fabric panels to be replaced or removed individually with the structure

erected without the need to deconstruct the shelter or completely unrestrain the arch base plates. The

fabric panels for the main bays of the structure shall be designed so the installation and removal can be

accomplished with all personnel on the ground. No fabric welding or heat-sealing may be used to

complete shelter fabric installation. The MLAMS is required to meet human factors and environmental

considerations as described in this document.

3.1.1 Physical Characteristics: The shelter arch structural members to be fabricated from lightweight

corrosion resistant materials. The shelter frames for the Type A, V and S shall be capable of converting

from one type to another through the addition or subtraction of components. The shelter shall be

modular in design, allowing for extended lengths via addition or matching arch structures. Shelter to

include external engineered system designed to resist water intrusion at the arch assembly joints and the

arch/fabric interface. All shelter support cabling shall be designed, fitted and provided with

preassembled or easily assembled terminal fittings equal to or greater than 80% of the catalog breaking

strength of the cable. All exterior hardware components and fittings, both metal and plastic, visible from

the exterior of the shelter, shall have no color requirements other than absence of polished or bright

reflective surfaces.

3.1.1.1 Recycled, recovered, environmentally preferable, or biobased materials: Recycled, recovered,

environmentally preferable, or biobased materials should be used to the maximum extent possible,

provided that the material meets or exceeds the operational and maintenance requirements, and promotes

economically advantageous life cycle costs.

3.1.1.2 Dimensions: Each of the Modular Large Area Maintenance Shelters shall have the following

center line dimensions:

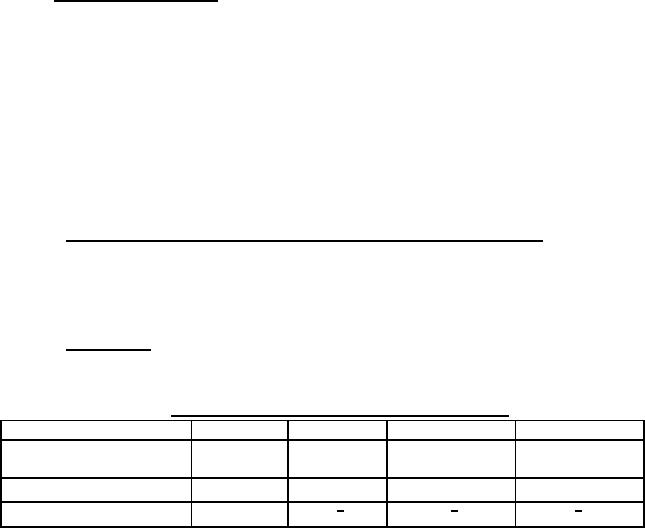

TABLE I. Centerline dimensions for MLAMS

Type

Width (ft)

Length (ft) Eave Height (ft)

Peak Height (ft)

+5,-2ft

192 +4,-5ft

15 +3.5,-1.5ft

31 +5,-0ft

Aviation (Type A)

75

+5, -2ft

128 + 7, - 3ft

15 +3.5,-1.5ft

31 +5,-0ft

Vehicle (Type V)

75

62 + 4ft

14 + 1ft

23 + 2.5ft

+5, -2ft

Storage (Type S)

45

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business